You know that artificial intelligence is demanding a massive amount of power, and while Big Tech wants to supply it with a nuclear renaissance, that could be years or decades away. To fill in the gap, power companies have a plan to set up gas power plants and transition them to nuclear waste reactors. First American Nuclear plans to build a gas power plant in Indiana by 2028, and then transition the plant to a liquid-metal fast reactor by 2032. The facility will reprocess and reuse spent fuel to reduce nuclear waste. First American Nuclear detailed the plan in the following press release:

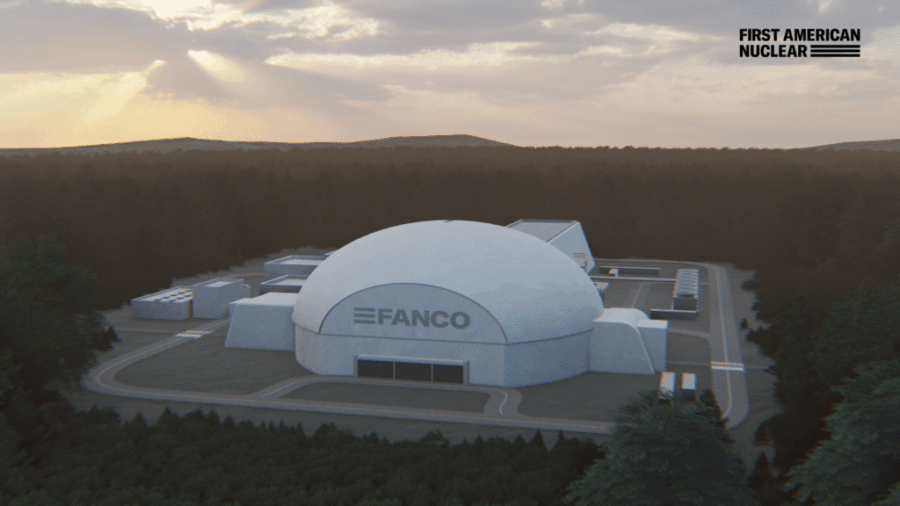

INDIANAPOLIS — November 4, 2025— First American Nuclear (FANCO), developer of a fast-spectrum small modular reactor (SMR) designed to deliver the most cost-effective utility-scale power in the world, and the State of Indiana today announced plans to establish Indiana as the home of the company’s headquarters, manufacturing facilities, and an energy park to position the state at the forefront of U.S. global leadership in sustainable nuclear technology.

“Indiana is leading the nation in the next chapter of American energy independence,” said Gov. Mike Braun. “With First American Nuclear planting its roots here, we’re bringing 5,000 high-paying, generational Hoosier jobs while cementing our state as a leader in clean, reliable nuclear power.”

The energy park is designed to be the first to operate in a “closed-fuel cycle” in U.S. history, meaning it will reprocess and reuse spent nuclear fuel on-site, eliminating 97% of long-lasting nuclear waste. The EAGL-1 reactor can also create more fuel than it burns, setting the stage for nuclear energy to be deemed not only clean, but renewable.

“In the flurry of America’s nuclear renaissance, Indiana and FANCO found a shared commitment to technical merit, authenticity, and follow-through,” said Mike Reinboth, CEO of First American Nuclear. “Collectively, our team has dedicated centuries to nuclear science, resulting in an unmatched nuclear solution that, fittingly, will take root in the crossroads of America.”

FANCO’s flagship technology, the EAGL-1 SMR, is the only nuclear technology in the U.S. cooled using a liquid metal alloy called lead bismuth. Having been involved in numerous commercial reactor deployments and nearly every major advanced nuclear project in the Western Hemisphere, the FANCO founders worked with sodium, molten salt, pressurized water, and high-temperature gas coolants for decades.

Their first-hand experience, combined with the knowledge that highly successful nuclear systems outside the U.S. are lead-bismuth cooled, convinced the team that lead bismuth solves the most arduous technical challenges to delivering safe, commercial-scale nuclear energy at an affordable price. Indeed, the EAGL-1 design generates 240 megawatts of electricity (MWe), enough to power 1.5 million homes from the typical six-reactor cluster, with a footprint one-tenth that of traditional nuclear power plants delivering similar MWe.

“Indiana and First American Nuclear joining forces to improve the quality of life for Hoosiers and the American people was an easy decision to make,” said Suzanne Jaworowski, Indiana Secretary of Energy and Natural Resources. “FANCO has the ability to deliver affordable, sustainable power to light up our rooms, keep us warm in the winter, cool in the summer, and rise to the ever-increasing energy demands of an advanced manufacturing and computing economy.”

The coolant is the key: why lead bismuth is a game-changer

Due to the benign chemical properties of lead bismuth, EAGL-1 does not require complex safety systems using exotic materials. The result is a compact, simple design with one-third less hardware than other SMRs and the ability to integrate seamlessly with off-the shelf power systems — all without sacrificing power. The EAGL-1 design will be manufactured and assembled with existing factory infrastructure and U.S. supply chains, driving further savings.

Yet another unique capability of FANCO is its proprietary solution to efficiently and cost-effectively transform existing coal plants into natural gas and, ultimately, to nuclear power with the same workforce and minimal changes to equipment. This provides immediate gas power to meet near-term needs while simultaneously fast-tracking a seamless and cost-effective transition to nuclear. Consumers get reliability without higher bills, and the State of Indiana attracts industry with access to an abundant, scalable energy supply.

In addition to tapping into Indiana’s existing workforce, First American Nuclear will develop a comprehensive program to attract and retain talent through partnerships with Indiana’s technical colleges and Universities,including tailored curricula, certifications, and apprenticeships. The program will build a pipeline of highly skilled local workers to support the manufacturing and operations of EAGL-1 nuclear components, and the deployment of these systems across the United States and around the world.

Action Line: Click here to subscribe to my free monthly Survive & Thrive letter. And read the latest issue, Survive and Thrive October 2025: Hunt Built a Better Boat.