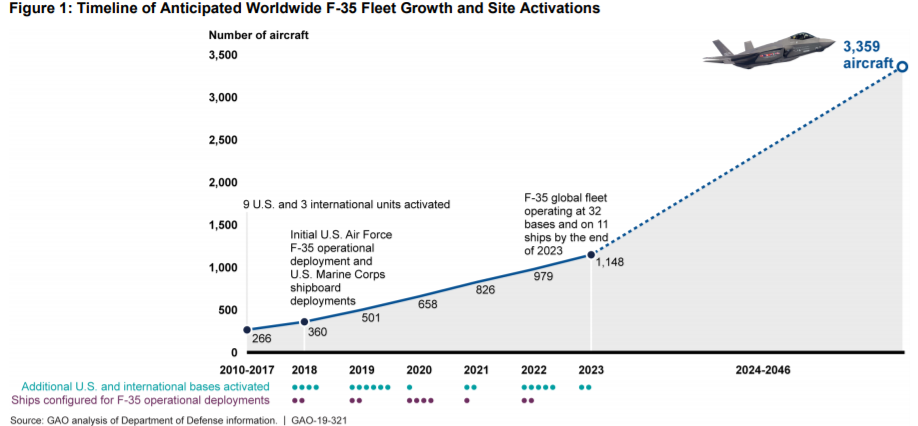

Lockheed Martin’s F-35 Lightning II is expected to fall short of former Defense Secretary Jim Mattis’ year-end 80% mission-capable rate. Lee Hudson of Aerospace & Defense Report tells readers that the main contributor to the delay is supply shortages for the F-35’s, most notably the transparency canopy. And it’s only going to get worse as worldwide fleet growth is expected to more than double by 2023. Lee Hudson goes on to write (abridged):

The Lockheed Martin F-35 Lightning II is not expected to meet the Pentagon’s goal of an 80% mission-capable rate by the end of the fiscal year due to supply shortages.

Transparency canopy shortages are the main obstacle in achieving the goal. The military is seeking additional sources to fix unserviceable canopies, Army Secretary Mark Esper, President Trump’s nominee for defense secretary, wrote on July 16 in response to previously prepared policy questions from the Senate Armed Services Committee.

Making matters worse, the GAO reports the DOD has been purchasing parts years ahead of time to support F-35 aircraft, but as the F-35 has been modified over time, those older parts don’t fit newer versions of the jet, forcing the Air Force to cannibalize its fleet for parts. In addition, the Pentagon will need to find new suppliers for critical parts for the Joint Strike Fighter. Turkish firms, responsible for hundreds of different parts for the F-35, most notably the cockpit displays and landing gear, will be kicked out of the program as a result of that country’s government purchasing Russian S-400 air defense systems. Joseph Trevithick of The Warzone writes (abridged):

It’s unclear what steps the U.S. Air Force might be taking in relation to the F-35A. Turkish firms have been the only suppliers for some 400 different parts for the F-35, Undersecretary of Defense [Ellen] Lord had added last month. Notably, electronics firm AYESAŞ builds the panoramic cockpit displays that go into all three variants of the F-35.

Also curious is what account the Pentagon is shifting these funds from. All $206 million is coming out of funding set aside for F-35 spare parts.

This is particularly notable given the difficulties the Navy, as well as the Air Force and the Marine Corps, have had in improving dismal availability rates across their respective F-35 fleets. By the end of 2018, Marine Corps F-35Bs were fully mission capable, on average, less than 15 percent of the time, while the rate for Navy F-35Cs was under five percent.

The exact reasons for these difficulties are multi-faceted and complex, something The War Zone has explored in detail previously, but the Pentagon’s central F-35 Joint Program Office (JPO) has previously identified shortages of spare parts, as well as existing stockpiles including parts that are no longer usable, as the “biggest factor impacting availability.”

Read more here.

Steve Schneider

Latest posts by Steve Schneider (see all)

- New Chinese Electromagnetic Surveillance Leaves “Nowhere to Hide” on Battlefield - March 15, 2024

- Amazon’s Nuclear Powered Data Center - March 7, 2024

- Skunk Works Rolls Out An Engineering Marvel - March 6, 2024

- Future of Airpower Takes First Flight - March 4, 2024

- A War Beneath the Waves – Trillions of Dollars at Stake - February 9, 2024